Poly Strapping vs. Polyester Strapping: Understanding the Key Differences

When it comes to securing and bundling items, strapping plays a crucial role in ensuring their safe transportation. However, with various types of strapping available in the market, it can be confusing to distinguish between them. One common dilemma is understanding the difference between poly strapping and polyester strapping. In this article, we will explore the characteristics, applications, and benefits of each type to help you make an informed decision.

The Composition: Poly Strapping

Poly strapping, also known as polypropylene strapping, is a type of plastic strapping made from the polymer polypropylene. It is a lightweight and cost-effective option for securing lightweight to medium-weight loads. Poly strapping is available in different widths, thicknesses, and strengths to accommodate various applications.

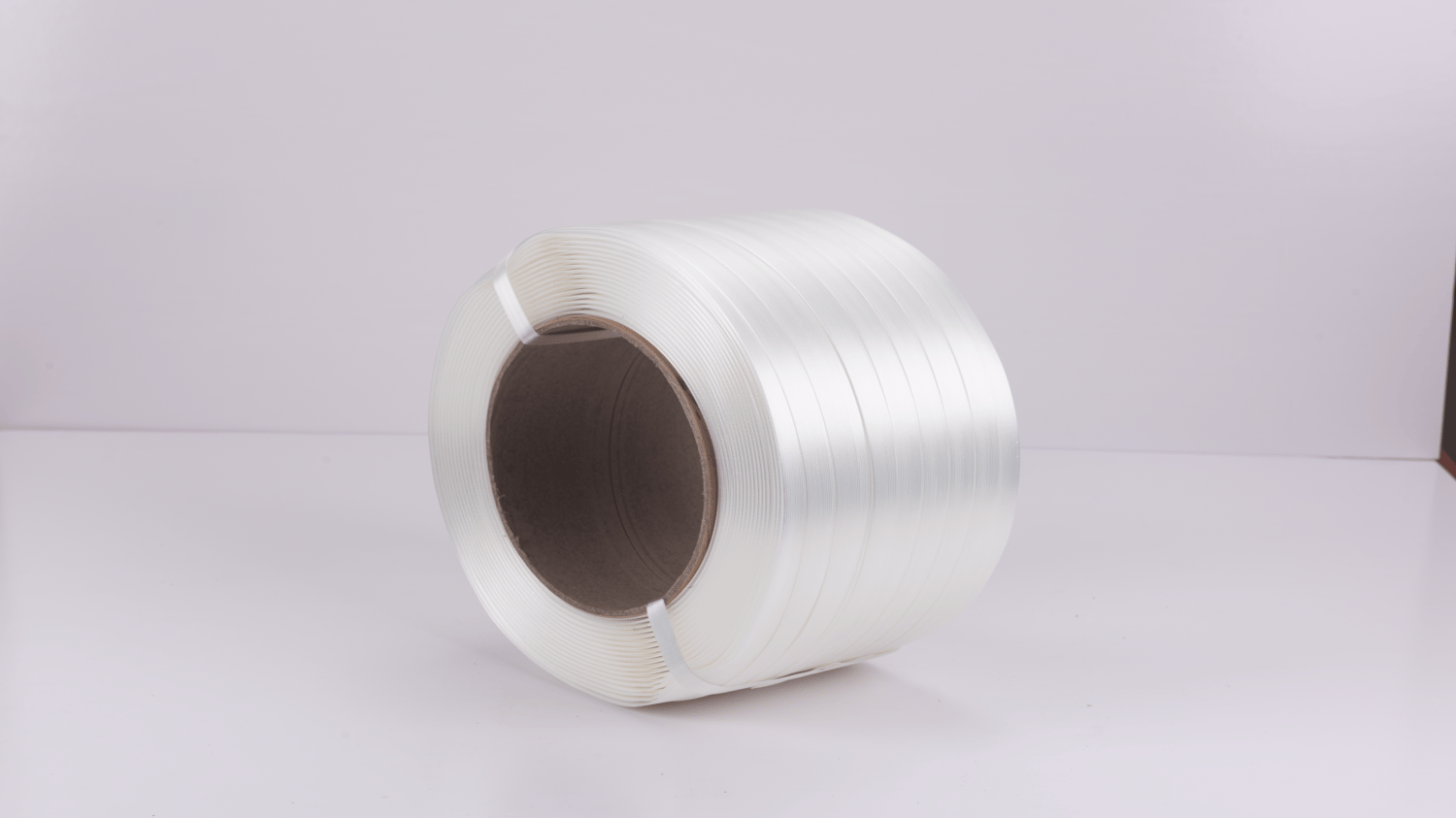

The Composition: Polyester Strapping

Polyester strapping, on the other hand, is made from polyester fibers. This type of strapping is known for its exceptional strength and durability. Polyester strapping is thicker and stronger than poly strapping, making it suitable for heavy-duty applications where high tension and load stability are required.

Strength and Tensile Properties

One of the primary differences between poly strapping and polyester strapping lies in their strength and tensile properties. Poly strapping has a lower tensile strength compared to polyester strapping. While poly strapping can withstand moderate tension, it is more prone to elongation and may not be suitable for securing heavy loads. On the other hand, polyester strapping has a high tensile strength, allowing it to handle heavy loads with minimal elongation.

Resistance to UV Rays and Weathering

When strapping is exposed to outdoor conditions or prolonged sunlight, its resistance to UV rays and weathering becomes critical. Poly strapping is susceptible to UV degradation and may weaken over time when exposed to direct sunlight. In contrast, polyester strapping exhibits excellent resistance to UV rays and weathering, making it a preferred choice for outdoor applications.

Elongation and Recovery Properties

Elongation refers to the ability of strapping to stretch under tension, while recovery is its ability to return to its original length after being stretched. Poly strapping has a higher elongation rate compared to polyester strapping, which means it can stretch more before reaching its breaking point. However, poly strapping has poor recovery properties and may not return to its original length, potentially compromising load stability. Polyester strapping, on the other hand, has minimal elongation and excellent recovery properties, ensuring load integrity even during transportation.

Applications of Poly Strapping

Poly strapping is commonly used in light to medium-duty applications. It is ideal for bundling and securing lightweight products such as boxes, cartons, and pallets. Poly strapping is widely used in industries like logistics, e-commerce, and manufacturing where cost-effectiveness and ease of use are key considerations.

Applications of Polyester Strapping

Due to its superior strength and durability, polyester strapping finds application in heavy-duty industries such as construction, lumber, steel, and shipping. It is suitable for securing heavy loads, such as construction materials, metal products, and machinery. Polyester strapping is also commonly used in challenging environments where exposure to extreme temperatures, moisture, or UV rays is expected.

The Cost Factor

Cost is an important factor to consider when choosing between poly strapping and polyester strapping. Poly strapping is generally more affordable than polyester strapping, making it a preferred choice for budget-conscious applications. However, it is essential to assess the specific requirements of your application and consider the long-term cost implications, such as potential damage or breakage, when making a decision.

Environmental Considerations

With increasing emphasis on sustainability, it is crucial to consider the environmental impact of strapping materials. Both poly strapping and polyester strapping are recyclable, making them environmentally friendly options. However, poly strapping is more commonly accepted by recycling facilities due to its wider usage and availability. Polyester strapping, while recyclable, may require more specialized recycling processes.

Choosing the Right Strapping for Your Needs

When deciding between poly strapping and polyester strapping, it is essential to assess your specific requirements. Consider factors such as load weight, transportation conditions, budget, and environmental considerations. If you require a cost-effective solution for light to medium-duty applications, poly strapping may be the right choice. However, if you need exceptional strength, durability, and load stability for heavy-duty applications, polyester strapping is the ideal option.