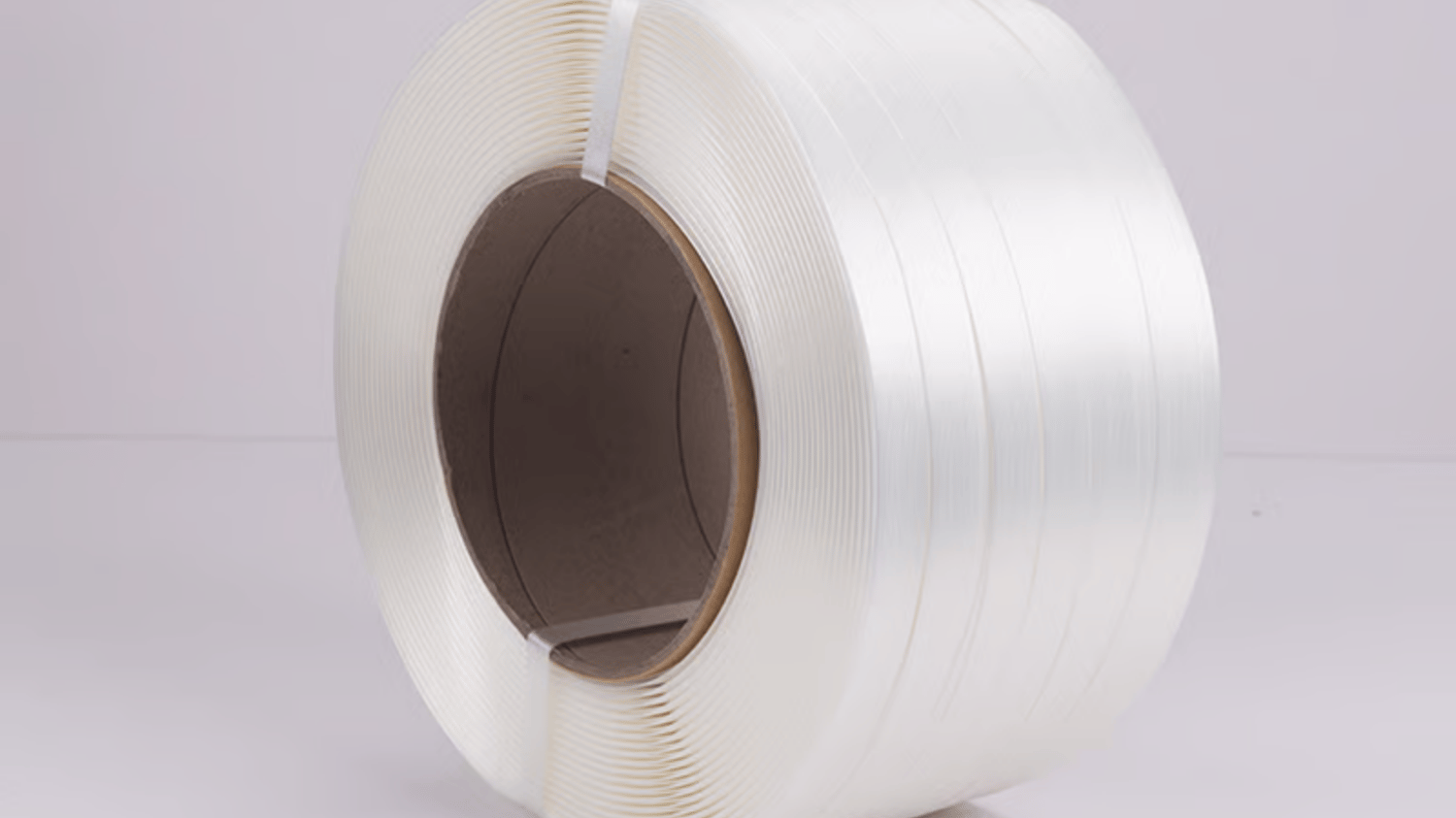

Understanding Composite Strapping

Composite strapping is a type of strapping used to secure heavy loads during transportation. It is made up of polyester fibers and a polymer coating, making it strong and durable. Composite strapping is commonly used in industries such as logistics, shipping, and manufacturing.

The Significance of Tensile Strength

Tensile strength is a critical factor to consider when using composite strapping. It refers to the maximum amount of force a material can withstand before breaking or snapping. Following proper tensile strength standards ensures that the strapping can effectively secure the load without risking damage or accidents.

Industry Standards for Tensile Strength

There are specific standards set by regulatory bodies and industry associations for composite strapping tensile strength. These standards dictate the minimum tensile strength requirements based on the type of load being secured and the transportation method used. Adhering to these standards is crucial for maintaining safety and quality.

Ensuring Compliance with Regulations

Companies that use composite strapping must ensure compliance with various regulations regarding tensile strength. This includes conducting regular testing and inspections to verify that the strapping meets the required standards. Failure to comply with regulations can result in fines, penalties, or even accidents.

The Impact of Tensile Strength on Load Security

The tensile strength of composite strapping directly impacts the security of the loads being transported. Insufficient tensile strength can lead to the strapping breaking during transit, causing the load to shift or fall. By following standards for tensile strength, companies can prevent such incidents and ensure the safe delivery of goods.

Benefits of Using High Tensile Strength Composite Strapping

Choosing composite strapping with high tensile strength offers several benefits. It provides greater security for heavy loads, reduces the risk of damage or loss, and enhances overall transportation efficiency. High tensile strength strapping is essential for securing valuable or fragile cargo.

The Role of Quality Control in Tensile Strength Standards

Quality control plays a crucial role in ensuring that composite strapping meets the required tensile strength standards. Manufacturers must adhere to strict quality control measures during the production process to guarantee the strength and reliability of the strapping. Regular testing is also essential to verify compliance.

Training and Education on Tensile Strength Standards

Proper training and education are essential for personnel involved in handling composite strapping. Employees should be knowledgeable about tensile strength standards and the importance of following them. Training programs help ensure that everyone understands the significance of compliance.

Continuous Improvement in Tensile Strength Technology

With advancements in technology, there is continuous improvement in the tensile strength of composite strapping. Manufacturers are developing innovative materials and coatings to enhance the strength and durability of strapping. Staying updated on these technological advancements is key to ensuring optimal load security.

Conclusion

In conclusion, adhering to composite strapping tensile strength standards is crucial for ensuring the safe and secure transportation of goods. By following industry regulations, conducting quality control measures, and using high tensile strength strapping, companies can minimize risks and enhance overall efficiency. Continuous improvement in technology further contributes to the reliability and performance of composite strapping.