Introduction

Composite strapping is a robust and versatile solution for securing heavy-duty loads during transit, offering superior strength and flexibility compared to traditional strapping materials. This guide explores the various sizes, benefits, applications, and considerations when choosing composite strapping for packaging needs.

H1: What is Composite Strapping?

Definition of Composite Strapping

Composite strapping is a high-strength packaging material made from multiple layers of materials, typically polyester fibers and polymer coatings. It combines the strength of steel strapping with the flexibility and safety of synthetic materials.

H2: Benefits of Composite Strapping

-

Strength and Durability: Composite strapping provides excellent resistance to impact and tension, ensuring secure transportation of heavy loads.

-

Safety: It absorbs shocks during handling, reducing the risk of injuries compared to steel strapping.

-

Cost-effectiveness: By reducing transport insurance premiums and damage claims, composite strapping offers long-term cost savings.

H3: Composite Strapping Sizes

1. Width

Composite strapping is available in various widths, typically ranging from 9mm to 32mm or more. The width choice depends on the size and weight of the load being secured.

2. Thickness (Thickness/Width Ratio)

The thickness of composite strapping varies relative to its width, ensuring optimal strength and load-bearing capacity. A higher thickness-to-width ratio indicates greater strength and durability.

3. Breaking Strength

Composite strapping sizes are rated by their breaking strength, measured in pounds (lbs) or kilograms (kg). This rating indicates the maximum load the strapping can safely secure without breaking.

H4: Applications of Composite Strapping

Industrial Packaging

Composite strapping is ideal for securing heavy machinery, steel coils, construction materials, and other industrial products during packaging and transportation.

Containerization

It enhances containerization by preventing cargo from shifting within shipping containers, thereby minimizing damage during transit.

Logistics and Transport

Used widely in logistics, composite strapping secures palletized loads during transportation via road, rail, sea, or air, ensuring safe delivery to destinations.

H5: Choosing the Right Composite Strapping Size

Factors to Consider

- Load Characteristics: Weight, dimensions, and stability requirements.

- Transportation Mode: Mode of transport and associated handling conditions.

- Environmental Factors: Temperature, humidity, and exposure to elements.

- Regulatory Compliance: Adherence to international standards for packaging and transport safety.

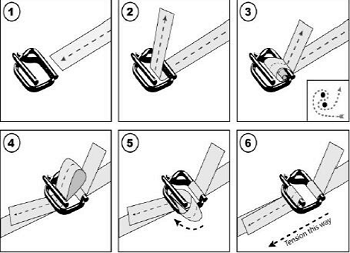

Installation and Tensioning

Follow best practices for installing and tensioning composite strapping to maximize security and stability of cargo, ensuring proper load distribution and minimal movement during transit.

H6: Sustainability and Environmental Impact

Recyclability

Composite strapping materials are often recyclable, contributing to sustainable packaging practices and reducing environmental footprint.

Regulatory Compliance

Ensure compliance with international standards and regulations governing the use of composite strapping in global trade and logistics to maintain safety and environmental standards.

FAQ - Frequently Asked Questions about Composite Strapping Sizes

Q1: What composite strapping size should I use for securing heavy machinery?

Select a composite strapping size based on the weight, size, and shape of the machinery. Opt for wider and thicker strapping for heavier machinery to ensure adequate support and security.

Q2: How do I calculate the required breaking strength for composite strapping?

Calculate breaking strength based on factors such as the weight of the load, coefficient of friction, and dynamic forces during transport. Ensure the strapping's breaking strength exceeds the maximum load to be secured.

Q3: Can composite strapping be reused?

Composite strapping can be reused if it remains in good condition after initial use. Regular maintenance and inspection are essential to ensure continued safety and performance when reused for securing subsequent loads.

Conclusion

Choosing the right composite strapping size is crucial for ensuring secure and efficient packaging solutions across various industries. By understanding its sizes, benefits, and applications, businesses can optimize cargo protection and operational efficiency during transport.